As the need for energy increases throughout the world, clean energy options are in particularly high demand, as environmental awareness and concern rise. Clean-burning natural gas (composed primarily of methane) plays an important role in meeting energy needs.

Many gas utilities and consumers are turning to propane for standby and secondary fuel systems to enhance security and flexibility, while also reducing the overall energy costs. Traditional systems using #2 fuel oil produce high emissions, are difficult to maintain, and add expensive secondary fuel systems to gas burning equipment. The majority of newer propane systems produce “propane-air” for direct replacement of natural gas during periods of gas curtailment. The fuel burning equipment operates just as if it is burning natural gas.

How it Works

Natural gas (NG) refers to a mixture of methane and various other hydrocarbons and inert gasses. Synthetic natural gas (SNG) typically refers to the output of coal gasification plants or refinery and petrochemical process streams. The term SNG may also be used to describe a mixture of a liquid petroleum gas (LPG) like propane and air. Propane-air is the most common LPG-air mixture that is used as a substitute or supplemental natural gas.

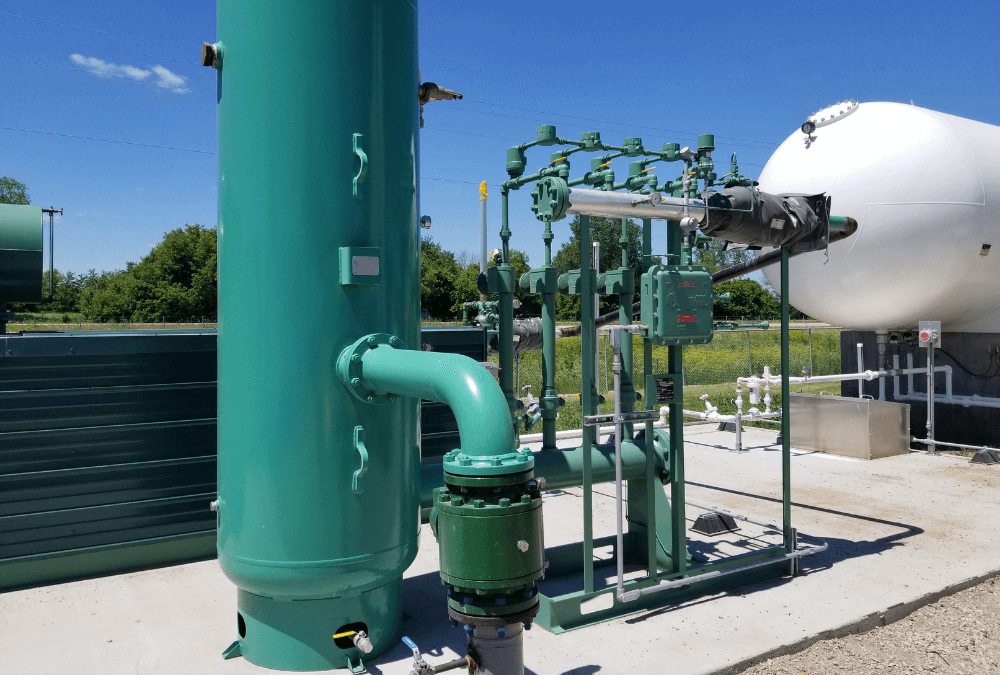

The general operation of propane standby systems generally begins with liquid being withdrawn from the storage tank. If necessary, the pressure is raised via a motor-driven pump. The liquid is then heated in a vaporizer and converted to a superheated vapor.

Vaporized propane can be piped directly to consuming appliances that are each equipped for dual-fuel (NG & LPG) firing. In most cases, propane vapor is first diluted with air to produce a “propane-air” mix. Propane-air is then distributed via the natural-gas piping for use without changes to individual burners.

Important Considerations

When considering propane-air, a few important considerations include projected cost savings, flexibility with regard to service interruptions, balancing requirements, and storage options.

The propane-system size and configuration will depend on several factors, including:

- Size of connected gas-consuming load

- Instantaneous flow rates

- Consumption – per hour, per day

- Insurance requirements

- And more

Lathrop Trotter Can Help

Our team has extensive experience in developing standby systems. We can help you with evaluating these considerations, and other planning details such as:

- System Layout

- Storage Tanks & Capacity

- Fuel Transfer

- Pumps

- Vaporizers

- Safety Systems

- Controls

- And More

The Lathrop Trotter team also advises on upgrades or retrofits that can provide energy savings, emissions reduction, improved controls, and more.

Our team works to assess and effectively address specific application needs. We provide highly customized, reliable systems that integrate seamlessly with existing processes. Contact us to discuss your project needs.

Questions? Your Lathrop Trotter sales engineer can help! Contact Us